Contents

- 1 How to Build Colorado Spinner Blades:

- 2 List of necessary materials:

- 3 Tools required for the project:

- 4 Selecting Blade Size and Color:

- 5 Hole Punching and Assembly:

- 6 FAQs:

- 7 Q: What is the advantage of building my own Colorado spinner blades?

- 8 Q: Can I use any type of metal for the spinner blades?

- 9 Q: How do I determine the right blade size for different fishing conditions?

- 10 Q: Are there specific color combinations that work best for Colorado spinner blades?

- 11 Q: Do I need any specialized tools for building Colorado spinner blades?

- 12 Q: How do I test the effectiveness of my custom spinner blades?

- 13 Q: Can I repair or modify my custom spinner blades after use?

Building Colorado spinner blades for fishing can be a rewarding and cost-effective way to customize your tackle. These flashy and effective blades are known for their enticing movement and ability to attract various fish species.

In this guide, we’ll explore a step-by-step process to create your own Colorado spinner blades, allowing you to tailor them to your preferences and increase your chances of a successful fishing experience.

How to Build Colorado Spinner Blades:

Colorado spinner blades are a popular component in fishing tackle, known for their effective and enticing movement underwater. These blades, typically made from metal, have a distinct teardrop shape and a larger surface area compared to other blade styles.

The design creates a significant amount of vibration and flash, attracting fish by mimicking the movement of wounded prey. Colorado blades are versatile and work well in various fishing conditions, making them a favorite among anglers.

Building your own Colorado spinner blades allows you to customize their size, color, and patterns, enhancing their appeal and increasing your chances of a successful catch.

List of necessary materials:

To build Colorado spinner blades, you’ll need a few materials. Here’s a list of the necessary items:

Spinner Blade Material:

- Brass or stainless steel sheet (preferred thickness depends on your fishing preferences)

- Pre-made Colorado spinner blade blanks (optional for beginners)

Cutting Tools:

- Tin snips or metal shears

- Hacksaw or jeweler’s saw (for more intricate cuts)

Shaping Tools:

- Round-nose pliers

- Needle-nose pliers

- Bench vise (optional but helpful)

- Small anvil or hard surface for shaping

Hole Punching:

- Metal hole punch or drill with metal drill bits (appropriate size for attachment)

Design and Pattern Tools:

- Permanent markers

- Engraving tools or fine files (for adding patterns)

Assembly:

- Split rings (size compatible with your blade and fishing lure)

- Fishing swivels

- Clevises (matching the size of your blade hole)

Testing and Adjustments:

- Fishing line and rod

- Barrel swivels

- Safety pin or similar for testing spin

Final Touches and Finishing:

- Sandpaper or polishing materials

- Clear nail polish or epoxy resin (optional for coating)

Safety Equipment:

- Safety gloves

- Safety glasses

Ensure you have a well-ventilated workspace and follow safety precautions when handling tools and materials. Additionally, adapt the sizes and quantities of materials based on your specific design preferences and fishing needs.

Tools required for the project:

To successfully build Colorado spinner blades, a set of essential tools will facilitate the process. First and foremost, cutting tools such as tin snips or metal shears are necessary for shaping the spinner blade material. A hacksaw or jeweler’s saw may also be required for more intricate cuts.

Shaping tools like round-nose pliers and needle-nose pliers are essential for crafting the distinct teardrop shape of Colorado blades. A bench vise and a small anvil or hard surface can aid in shaping the blades effectively. Hole punching tools, such as a metal hole punch or a drill with metal drill bits, are crucial for creating attachment points.

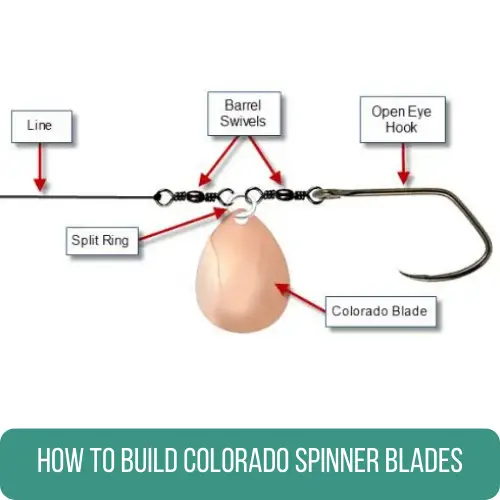

For adding patterns and designs, permanent markers and engraving tools or fine files will be helpful. Assembling the blades requires split rings, fishing swivels, and clevises, with sizes matching the blade and fishing lure. Testing and adjustments involve fishing line, a rod, barrel swivels, and a safety pin for assessing the spin.

Finally, for finishing touches, sandpaper or polishing materials, along with optional clear nail polish or epoxy resin, can be used for coating. Safety gloves and safety glasses are essential for protecting yourself during the construction process.

Having these tools on hand will contribute to a smoother and more successful Colorado spinner blade building project.

Selecting Blade Size and Color:

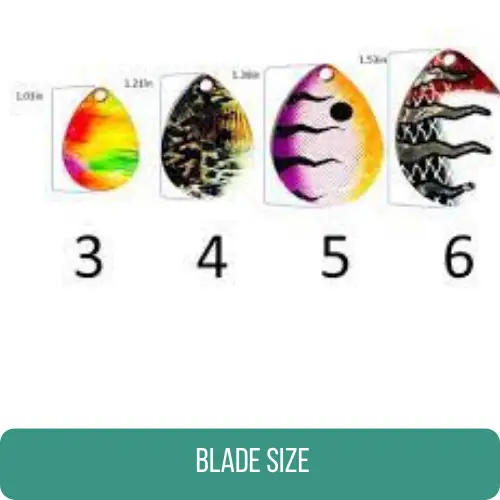

Selecting the right blade size and color is crucial for optimizing the effectiveness of your Colorado spinner blades. The size of the blade directly influences the amount of vibration and flash it produces underwater, affecting its ability to attract fish.

Larger blades create more resistance, resulting in slower rotations with increased vibration. Smaller blades, on the other hand, spin faster but generate less vibration. Consider the specific fishing conditions, such as water clarity and the target fish species, when choosing the size.

Additionally, color plays a significant role in attracting fish. Bright and contrasting colors are effective in murky water, while more natural and subdued colors work well in clear conditions.

Experimenting with various color combinations and patterns can help determine the most effective choices for your local fishing environment.

Ultimately, the ideal blade size and color depend on the specific fishing scenario and the behavior of the target fish. It’s advisable to have a variety of sizes and colors in your tackle box, allowing you to adapt to different conditions and increase your chances of a successful catch.

Hole Punching and Assembly:

Hole punching and assembly are critical steps in building Colorado spinner blades, ensuring proper attachment and functionality. Here’s a breakdown of the process:

Hole Punching:

- Use a metal hole punch or a drill with metal drill bits to create a hole in the top of the blade for attachment.

- The size of the hole should match the size of the split ring or clevis you plan to use for connecting the blade to your fishing lure.

Assembling the Blade:

- Begin by attaching a split ring through the hole in the blade using round-nose pliers. Make sure the split ring is securely closed.

- Connect a clevis to the split ring, and then attach another split ring to the other end of the clevis.

- The second split ring is used to connect the blade assembly to the fishing lure or swivel on your fishing line.

Choosing Clevis Size:

- Ensure the clevis size matches the hole size in your spinner blade. Clevises come in various sizes, and choosing the right one is crucial for proper spinning action.

Securing Connections:

- Use needle-nose pliers to close the split rings securely. This ensures that the blade assembly remains intact during use.

Testing Spin:

- Before fishing, test the spin of the assembled blade by attaching it to a safety pin and allowing it to rotate freely. Ensure that the blade spins smoothly without any obstructions.

Making Adjustments:

- If the spin is uneven or the blade wobbles, you may need to make adjustments. This could involve tweaking the shape of the blade or adjusting the size of the hole for better balance.

By carefully executing the hole punching and assembly steps, you create a well-functioning Colorado spinner blade ready for use in your fishing endeavors. Regularly check the connections for wear and tear to maintain the effectiveness of your custom blades over time.

Conclusion:

In conclusion, building your own Colorado spinner blades provides a customized and rewarding approach to enhancing your fishing tackle. By carefully selecting blade size, color, and patterns, and following the steps of cutting, shaping, hole punching, and assembly, you can create effective and personalized lures.

Experimenting with different configurations allows you to adapt to various fishing conditions and increase your chances of success. Remember to prioritize safety, test your creations before use, and enjoy the satisfaction of crafting your unique fishing gear.

FAQs:

Q: What is the advantage of building my own Colorado spinner blades?

A: Building your own Colorado spinner blades allows for customization in terms of size, color, and patterns, tailoring them to specific fishing conditions and preferences. It can be a cost-effective and rewarding way to create effective lures.

Q: Can I use any type of metal for the spinner blades?

A: Brass or stainless steel sheets are commonly used for spinner blades due to their durability and corrosion resistance. Choose a thickness that suits your fishing preferences.

Q: How do I determine the right blade size for different fishing conditions?

A: Larger blades create more vibration and are suitable for murkier waters, while smaller blades spin faster and work well in clearer conditions. Consider the target fish species and water clarity when choosing blade size.

Q: Are there specific color combinations that work best for Colorado spinner blades?

A: Bright and contrasting colors are effective in murky water, while more natural and subdued colors work well in clear conditions. Experiment with different color combinations and patterns to find what works best in your local fishing environment.

Q: Do I need any specialized tools for building Colorado spinner blades?

A: Basic tools like tin snips, pliers, drills, and hole punches are essential. Safety gloves and glasses are recommended. You can gradually invest in more specialized tools based on your preferences and the intricacy of your designs.

Q: How do I test the effectiveness of my custom spinner blades?

A: Before fishing, test the spin of the assembled blade by attaching it to a safety pin and allowing it to rotate freely. Ensure smooth and balanced rotation to maximize the lure’s effectiveness in the water.

Q: Can I repair or modify my custom spinner blades after use?

A: Yes, you can make adjustments to the blade shape or size of the hole if needed. Regularly check for wear and tear on connections and make repairs as necessary to maintain optimal performance.